E-Commerce and Marketplace Analytics

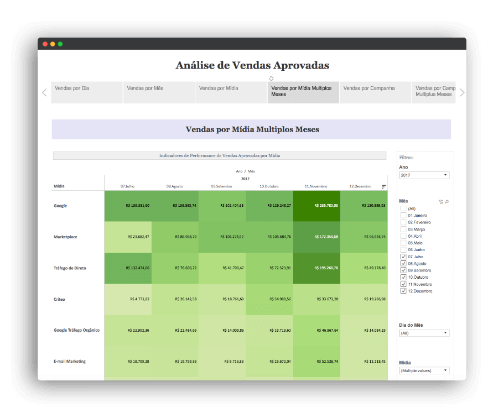

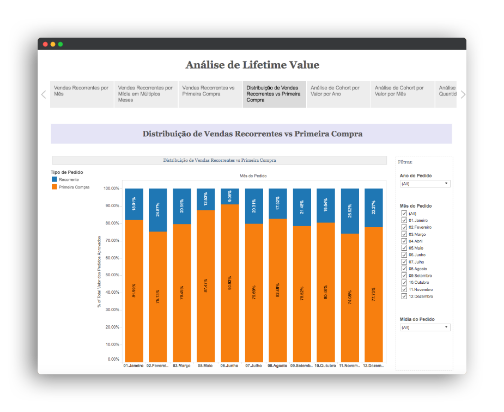

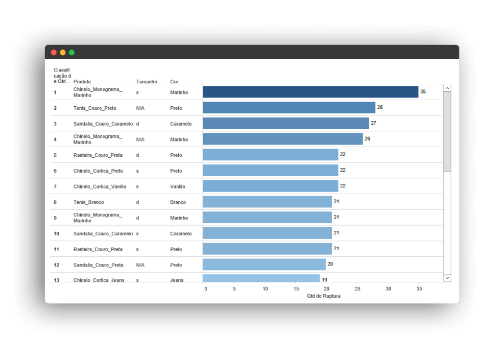

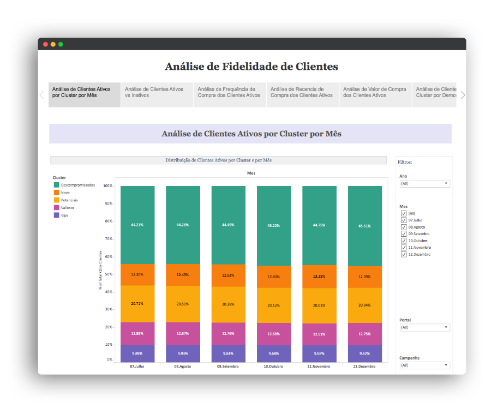

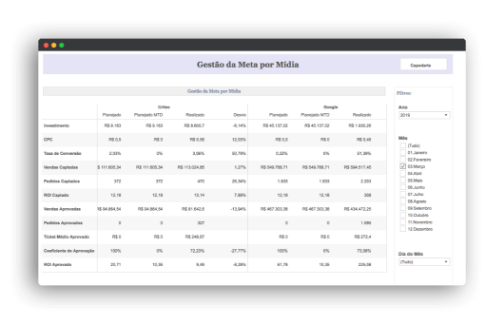

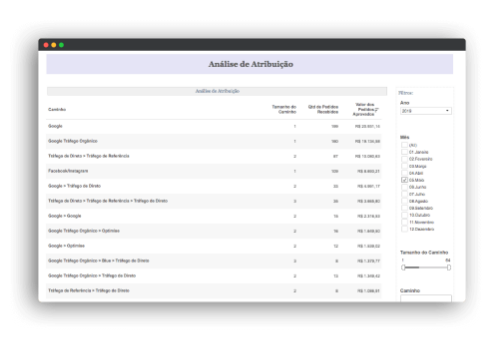

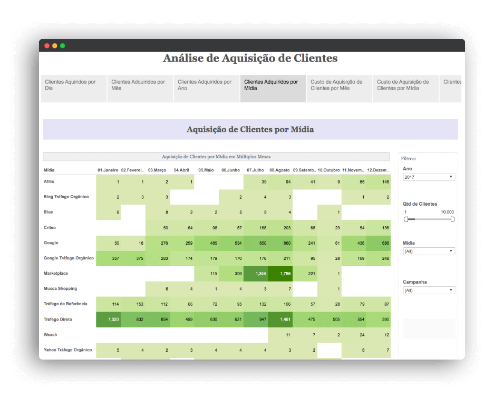

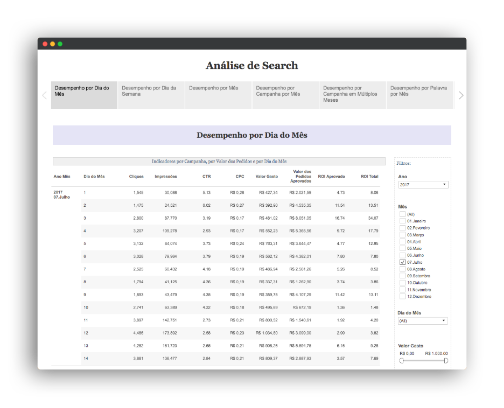

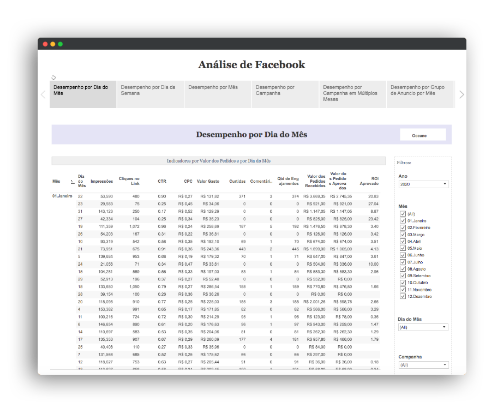

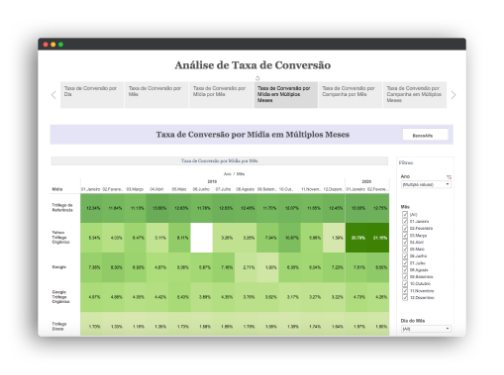

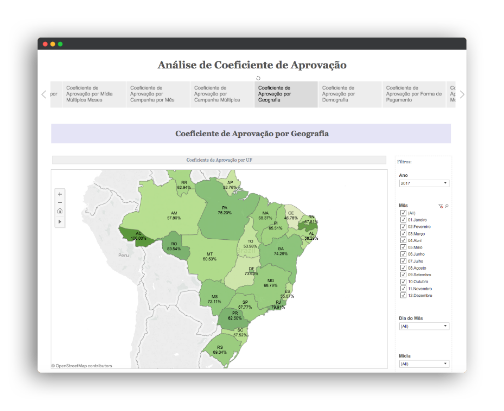

Plataforma de inteligência analítica que fornece insights para a melhoria do resultado de seu e-commerce ou marketplace, com dados de mídia por valor aprovado, indicadores de lifetime value, custo de aquisição e clientes, ruptura, atribuição por valor aprovado e muito mais.